An important step to better lithium-ion batteries can be found in Whoop's latest wearable

Why it matters: It oft seems like bombardment applied science hasn't been keeping up with advances in compute power for the tiny chips that ability mobile devices. That'southward because making batteries cheaper and easier to manufacture has been a far easier problem to solve than improving their energy density, charging fourth dimension, endurance to constant charging and discharging, all while ensuring they remain relatively safe during performance. News of breakthroughs comes and goes, only we at present have i that's making it into an actual production, courtesy of Sila Nanotechnologies.

This week, fitness tracking company Whoop unveiled a new wearable that crams a lot of circuitry and sensors into a tiny package that you tin can comfortably wear on your wrist. It's an impressive piece of kit focused on collecting metrics about your heart rate, sports activity, sleep functioning, skin temperature, blood oxygen levels, and more. But what makes this device fifty-fifty more than impressive is that it's 33 per centum smaller in volume compared to its predecessor while all the same existence able to last five days before needing to be charged once again.

What made this possible may seem like a simple change, but it's actually the effect of ten years of arduous piece of work from a startup chosen Sila Nanotechnologies, founded by 1 of Tesla's early employees, Cistron Berdichevsky. The Alameda-based visitor is backed past BMW and Daimler and has been working since 2022 on finding a meliorate anode material for batteries that would ameliorate their characteristics.

That cloth is silicon, whose atoms theoretically accept the potential to hold ten times the number of electrons when compared to graphite, which is a commonly used anode material. But as other companies researching silicon for utilise in anodes accept establish over the years, this isn't easy to translate into practice, as engineers have had to add complication to the traditional lithium-based bombardment blueprint to mitigate safety and longevity bug.

The major challenge with silicon is that during charging, it expands to more three times the original size as a upshot of reacting with the lithium, and then as well contracts more than three times during discharging, posing slap-up risks to the structural integrity of the battery. For reference, graphite merely expands around seven percent with charging and contracts 7 percentage with discharging.

Battery manufacturers such as Panasonic have been trying to solve this in diverse ways, by and large by adding small amounts of silicon into the anode mix -- typically 3-five percent, but never more than ten percentage. Companies that tried making pure nano silicon anodes have found the resulting batteries don't concluding more than 100 accuse-discharge cycles without expensive mitigations that would make mass manufacturing unfeasible from a financial perspective. Startups like XNRGI that are etching batteries on silicon wafers are a good example of that.

Sila says it has found a way to eventually replace graphite entirely and allow for upwards to 20 percent higher energy density while all the same using existing battery manufacturing techniques. This is one of the main advantages of Sila's silicon anode, forth with the fact that the raw materials needed are widely bachelor and thus less decumbent to global supply shortages.

All of it is fabricated possible cheers to an engineered particle structure that allows the silicon to aggrandize within of it while keeping the electrolyte outside. In turn, the battery tin now be cycled thousands of times without posing any safety issues. Berdichevsky says the anode in Whoop 4.0's battery can last for more than 500 full charge-belch cycles, which translates into several years of normal apply.

That's only the get-go, however, as this bombardment only has an anode with 25 percent silicon in it, so in that location'south withal a lot of room for improvement. Launching the technology inside a small wearable may not await like much, merely Berdichevsky is convinced it will gradually "scale and lead to the electrification of everything." He says, "you lot can interpret this success with Whoop to cars in many means," such equally making affordable compact sedans with 400 miles of range a reality in the hereafter.

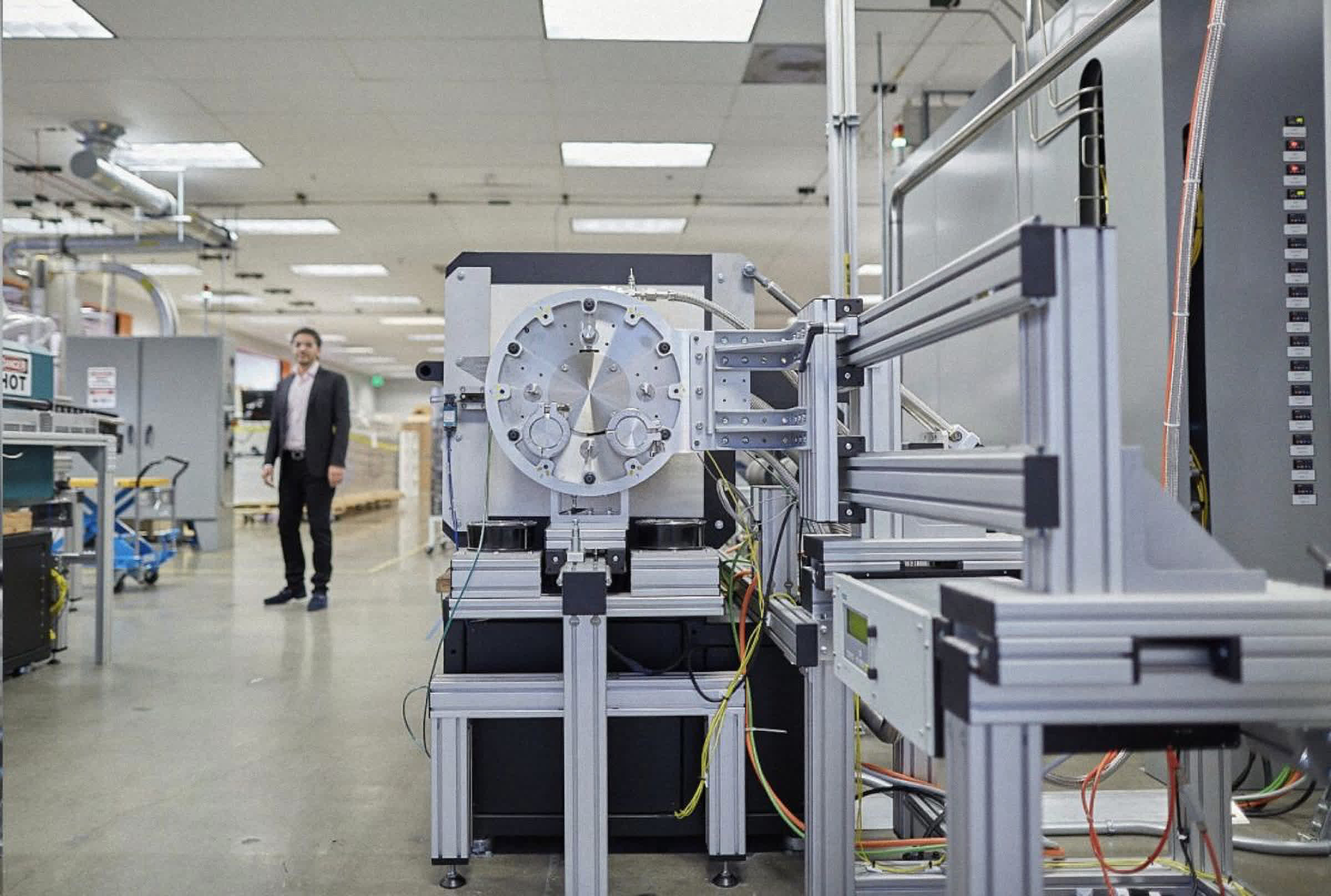

Getting into EV territory requires a highly-scalable manufacturing procedure, and the skillful news is that Sila has had that baked into the company'due south mission from the very start. Information technology has been developing volumetric reactors that accept a much higher production chapters than planar reactors. And then far, information technology has scaled 10,000 times from lab to the latest reactor, which has a capacity of 5,000 liters.

The plan is to scale that up 100 times to a reactor large enough to drive a automobile through, which would be enough to produce the large amount of batteries required to make full electric cars. Sila is also looking to build a larger manufacturing plant in the next few years, thanks to $590 one thousand thousand raised earlier this year from investors.

We're not there yet, only after more than a decade of promises and billions spent on research that didn't seem to materialize in any meaningful manner, things are looking bright for the batteries that will power our electrified future.

Source: https://www.techspot.com/news/91169-important-step-better-lithium-ion-batteries-can-found.html

Posted by: beauchampsevenjoy.blogspot.com

0 Response to "An important step to better lithium-ion batteries can be found in Whoop's latest wearable"

Post a Comment